AUTOMATIC STAMP PRODUCTS

Precision Metal Stampings Est. 1941

Precision Metal Stampings

Est. 1941

ISO 9001:2008 Registered

Capabilities

Production Capabilities

- Multi-Slide®

- Fourslide

- Conventional Press

- Hydraulic Press

- Secondary Operations

- Tapping

- Spot Welding

- Specialized Operations

- Deburring, Washing

- Heat Treat, Plating

- Assemblies

Range of Services

Markets and Customers

Capabilities > Production Capabilities

Multi-Slide®

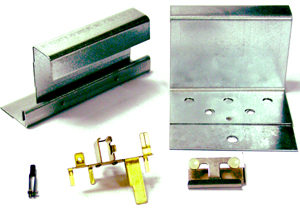

Automatic Stamp Products specializes in the use of US Baird Multi-Slide® Machines. Our equipment can handle up to five 40-ton rams plus auxiliary equipment, a vertical stripping unit, and up to six forming slides. We also have the capability of a 100-ton Toggle Press on our larger machines. Stampings can be positively clamped in the progressive dies for superior control of operations such as performing, lancing, coining, extruding, and deep drawing, thus eliminating the reliance on springs.

Since 1959 we have incorporated in-die form thread tapping on the Multi-Slide®. Prefabricated parts can be hopper feed and assembled into the stamping. In many cases, material scrap can be reduced because the material width can be ordered as the finished width of the part. All of this allows for cost effective tooling for complex parts, thus eliminating secondary operations and handling resulting in lower piece part costs.

Maximum material dimensions our equipment can handle are 0.093” thick, 5” wide, and 13” progression. Back to top

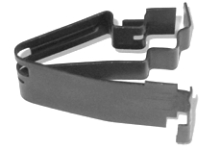

Fourslide

Automatic Stamp Products can handle your wire forming needs for round, square, or rectangular wire. Our capacity is 3/16” dia. or thickness, up to 1 1/8” wide, and up to 26 1/2” feed. Back to top

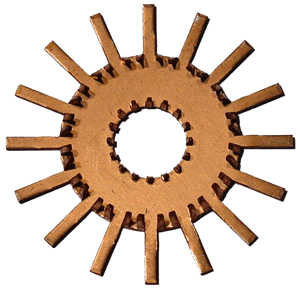

Conventional Press

For stampings that do not require complex forming use of a conventional press may be cost effective. With a capacity of up to 100 tons, our conventional presses can handle materials up to 1/8” thick and 8” wide. Back to top

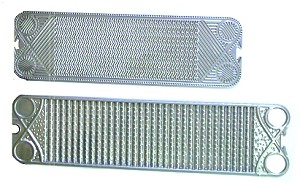

Hydraulic Press

For large stampings requiring piercing, notching, forming or drawing applications, we have a 1,500-ton hydraulic press to serve your needs. Current applications include producing heat exchanger plates that are 1/16” thick x 60” wide x 62” long. Back to top

Secondary Operations

Depending on the design of your stamping, secondary operations sometimes are necessary to meet your requirements. Automatic Stamp Products provides a wide range of options to meet your needs. A few examples are listed below.

- Tapping: Some stampings, because of their configuration, cannot be tapped in the Multi-Slide® or the press. We offer hand feed or bowl feed automatic operations.

- Specialized Operations: Automatic Stamp Products can design, build, and operate hand feed or automated customized equipment to meet your needs or we can operate your equipment at our facility.

- Deburring, Washing: We can deburr your stampings to your specifications and also remove the lubricants used in the stamping operation. A rust inhibiter can be applied for steel parts.

- Heat Treat, Plating: Although Automatic Stamp Products does not heat treat and plate stampings in house, we work with our partners who specialize in these processes, most of which are located within 50 miles of our facility. All are ISO and/or TS certified companies assuring you that your heat treat and plating needs are met to your specifications.

- Assemblies: Automatic Stamp Products can design, build, and operate hand feed or automated customized assembly equipment to meet your needs or we can operate your equipment at our facility.